When it comes to producing a quality product at a rate that meets consumer demand, not all businesses can handle everything on their own. Smaller companies, in particular, often struggle to obtain the necessary resources to manage all manufacturing processes in-house. Fortunately, with the right contract manufacturer, you can still thrive in the market. This complete guide to understanding contract manufacturing will teach you the importance of these partnerships and how to find one for your business.

The Basics of Contract Manufacturing

Contract manufacturing is a mutually beneficial process for both parties involved. A business owner sells their product to consumers, while the contract manufacturer builds either parts of the item or the entire item to ship. This allows both entities to play to their strengths, resulting in a higher-quality product for the customer. Working with a contract manufacturer can be incredibly beneficial for the long-term success of your business. However, to get the most out of this partnership, you’ll need to provide the contract manufacturer with the product specifications and authorize them to make necessary design tweaks. Some contract manufacturing companies even offer engineering services, allowing them to design specific parts or products according to your guidance. This means you won’t have to navigate the planning stages alone.

The Types of Contract Manufacturing

There are several types of contract manufacturing that you can utilize in your business, and some may complement your operations better than others. It’s crucial to understand your options before negotiating a contract. Here are some of the most common types of contract manufacturing and their general terms, noting that processes can vary slightly depending on the company you partner with.

Component Manufacturing

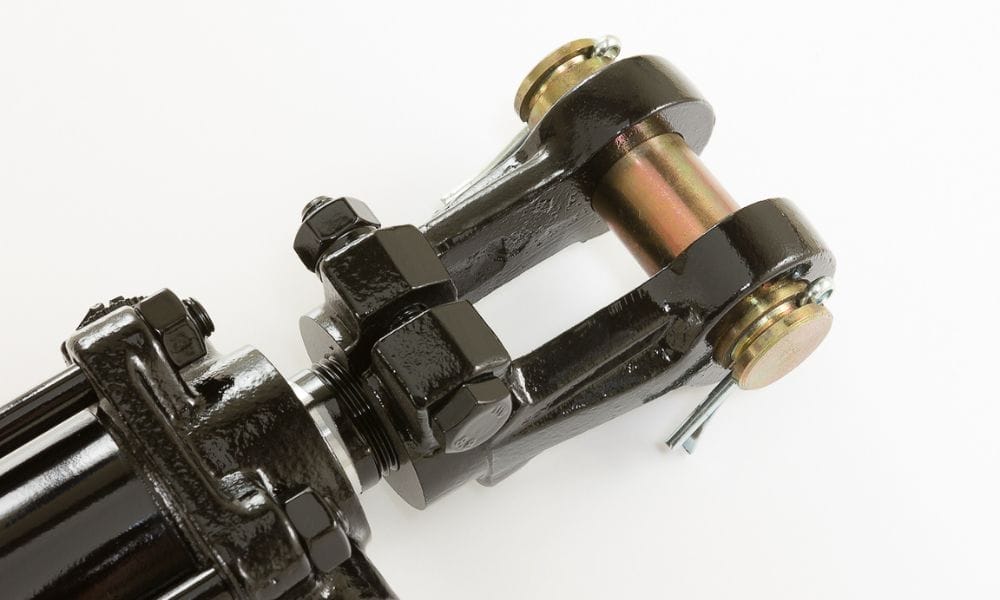

Component manufacturing contracts cover the creation of select parts of your desired product. Car companies are a prominent example of this type of partnership. While automotive companies produce their vehicles, creating the parts for their cars often requires contract manufacturing resources. For larger, more complex builds, outsourcing a few projects can significantly improve production efficiency.

Labor Contracting

You can also contract labor from outside sources. Smaller companies often lack the workforce to manufacture products on their own. In these cases, they contract employees from contract manufacturing companies to fill the gap. The business still owns its manufacturing facilities but outsources the labor itself.

Equipment Rentals

If a company has the workforce but not the equipment to produce its product, they can rent facilities. Buying equipment can be incredibly costly and delay profitability for several months. Renting machines from other businesses can promote flexibility, save money, and ensure continued production of high-quality products.

Full Product Production

Some contract manufacturing companies offer full-scale production services, meaning they produce the entire product for you to sell and ship as needed. This form of contract manufacturing is the most expensive because it uses the most resources. However, even though the process takes place outside your business facilities, you still have full control and can sell products with your brand attached.

The Benefits of Contract Manufacturing

There are various contract manufacturing options, each with its own advantages and disadvantages. Partnering with an outside company offers many general benefits to consider. Here are some of the most important benefits you’ll gain from these contracts:

Better Resource Allocation

For small- and medium-sized companies, internal resources can be scarce. Outsourcing your manufacturing processes provides you with additional manpower and technology for key internal operations. This prevents your team from being spread too thin and allows you to grow your company without worrying about stock and productivity.

Access to Skilled Engineers

Contract manufacturing gives you access to a team of skilled designers and engineers. Even if your own team lacks manufacturing expertise, these professionals will use their knowledge to bring your vision to life. With these contracts, you’ll have several trained and talented experts working for you without the need to screen or hire them individually.

Faster Product Creation

Having a team of professionals who know how to use the equipment effectively leads to faster product output. These skilled technicians can streamline the production process to maximize the amount of product in a shorter time. This allows you to fill orders quickly and keep up with rising demand.

Cost Savings

While contract manufacturing services can be expensive, they are much less costly than bringing these processes in-house. Equipment alone can cost your company billions, not to mention labor and management technologies. Therefore, contract manufacturing is a more budget-friendly option as your business grows.

Superior Quality Control

Working with a contract manufacturer ensures the quality of the resulting products. These companies have their own internal quality control procedures to ensure you can take pride in every item that leaves their facility. They strive to ensure your satisfaction and will go the extra mile to achieve it.

Tips for Choosing a Contract Manufacturer

No guide to understanding contract manufacturing would be complete without tips for finding your own contracted partner. As mentioned, all contract manufacturing companies have different offerings and approaches to the creation process. It’s vital to choose your partnership carefully and ask questions to see if the prospects align with your business needs. Interview several options to understand their capabilities.

Check their level of experience in the industry and their overall reputation among other businesses. Client reviews can provide key insights into what it’s like to work with a particular team. If you notice regular negative responses, it might be time to look elsewhere. Conversely, companies with positive reviews and high-quality ratings should warrant a closer look.

At Swisher, we pride ourselves on offering a range of contract manufacturing solutions. As a premium contract manufacturing company, we excel in processes such as powder coating, part fabrication, welding, and assembly. When you partner with us, you gain a team that can meet any of your manufacturing needs. We also provide logistics and distribution services, allowing you to ship the products we build directly to your customers. Contact us today to discuss your contract manufacturing needs.