The manufacturing sector is always evolving, and 3D printing technology is the latest game-changer in metal fabrication. This innovation alters how we craft products and redefines the parameters of creativity and efficiency in the industry. For business owners navigating this terrain, understanding the impact of 3D printing can unlock new levels of innovation and competitiveness. Here’s how 3D printing is changing metal fabrication for the better.

The Benefits of 3D Printing in Metal Fabrication

Using 3D printing offers a series of advantages to metal fabrication that appeal to a manufacturer’s bottom line and ethical considerations.

Cost-Effectiveness and Efficient Production Processes

One of the most compelling benefits of 3D printing is its cost-efficiency. Traditional fabrication methods require expensive molds or tools before production can begin. In contrast, 3D printing eliminates the need for such investments, allowing for direct construction from digital models. This method significantly reduces production times and enables rapid prototyping, which is valuable for testing and development.

Design Flexibility and Customization Options

The constraints of traditional manufacturing processes often force designers to prioritize manufacturability over the ideal design. However, 3D printing liberates designers from these restrictions, enabling the creation of complex structures that would otherwise be impossible or prohibitively expensive to produce. Such flexibility opens the door to customization and innovation, allowing businesses to cater to client needs or niche markets more effectively.

Sustainability and Reduced Material Waste

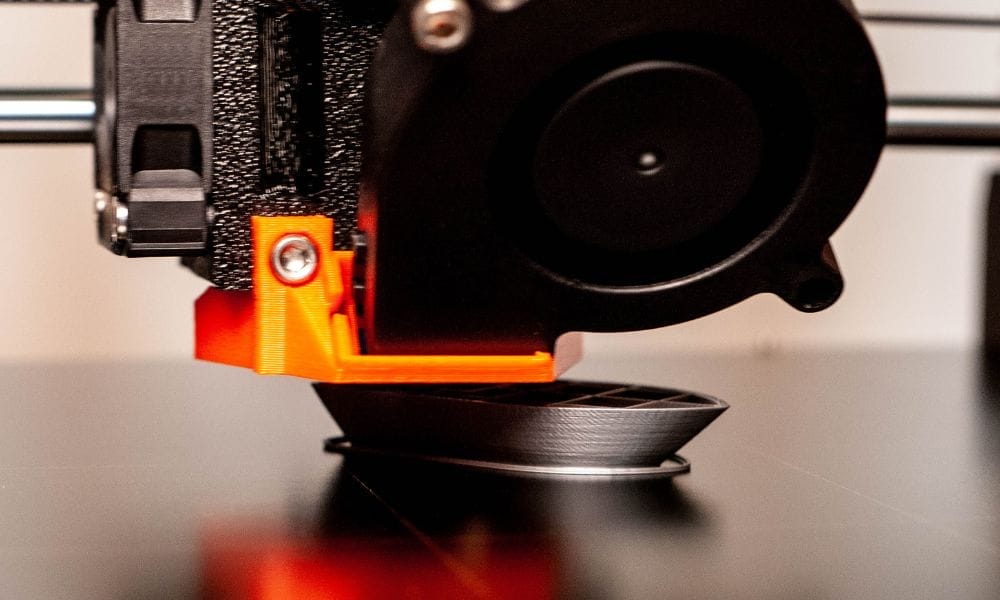

Sustainability is another striking way 3D printing is changing metal fabrication. Traditional metal fabrication can be wasteful, with excess material trimmed away and discarded. Comparatively, 3D printing is additive, building objects layer by layer and using material only where needed. This process reduces waste and contributes to more environmentally friendly manufacturing practices.

The Impact of 3D Printing on Traditional Metal Fabrication Businesses

The rise of 3D printing technology compels traditional metal fabrication businesses to reevaluate their models and adapt to survive in this new landscape.

Changes in Business Models and Client Interactions

Adopting 3D printing allows for a more collaborative approach with clients. The ability to produce prototypes quickly means manufacturers can refine designs in close consultation with clients, improving satisfaction and engagement. This approach to design and manufacturing may require businesses to rethink operations and client management strategies.

The Need for Upskilling and Adapting to New Technology

The shift toward 3D printing also necessitates investment in new skills and technology. Workers familiar with traditional fabrication methods must adapt to operate advanced 3D printing equipment and software. This transition represents a significant challenge and an opportunity for growth and development within the industry.

Currently, 3D printing is transforming the landscape of metal fabrication, offering flexibility, efficiency, and opportunities for innovation. Business owners interested in staying competitive should consider exploring the possibilities of 3D printing for their operations. At Swisher, we’re always on the lookout for new ways to deliver superior custom fabrication services, and 3D modeling is becoming a core part of our processes. Whether you’re in the later stages of design or have an idea in your head, we can help you make your product tangible.